- Tab Welding

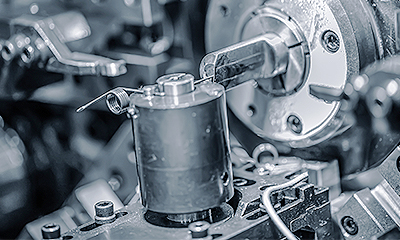

- Automatic welding process for stacked cell by means of 'Ultrasonic welding process' between Anode, Cathode aluminum collector and Ni-Tab, Al-Tab.

Overview

Experience in various ultrasonic metal welding has been combined with equipment manufacturing technology.

Various welding techniques such as 'Ultrasonic Metal Welding', 'Resistance Welding', 'Laser Welding', etc. can be applied.

Cooperating with global welder makers who can install and provide after-sales service not only in the Americas but also in Europe.

*Process Flow

Cell Loading → Start Button → Cell Gauging → Pre-Welding → Tab Cutting → Re-Gauging Cell → Tab Welding → Unloading

- Separate operation between Anode and Cathode is recommended as 2 set configuration

- After stacked cell loading, fully automated process as one cycle

- For guarantee of best welding quality, 'Pre-Welding' and 'Main-Welding' required to be separated

Specification

* All specifications are custom designed according to customer's needs

| Items | Specification | Remark |

|---|---|---|

| Pre-Welding & Tab Welding | Ultrasonic 2set (Mode Change) | |

| Lead Assembly Loading | Magazine | |

| Tab Cutting Unit | Auto (After Pre-Welding) | |

| Control | PLC, Touch Panel | |

| Dimension (WxLxH) | 1150*1100*2,000 | |

| Cell Size | T.B.D | T.B.D |

| Capacity (PPM) | T.B.D | T.B.D |

| Tab Welding | Ultrasonic Welder | |

| Frequency | 20 / 35 / 40 Khz | |

| Power Output | 800 / 1000 / 1500 / 4000 Watts | |

| Driving | Pneumatic |

Contact us

- Pouch Cell Ass'y