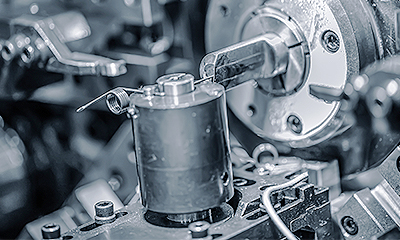

- Electrode Punching & Cleaning

- Punching coated electrode supplied from a roll by using precision mold to meet user's demand.

Overview

Expandable production capacity on the basis of user needs.

Dealing with a wide range of punched electrode dimension.

Adding optional solution such as cleaning electrode surface based on user needs.

*Process Flow

Electrode Unwinding (Roll) → Feeding → Electrode Punching → Feeding → Cleaning(Roll Brush) → Magazine Loading

- 2 Set recommended for one is 'Anode' and the other one is 'Cathode'

- Precise Burr Spec : ≤ 10μm

- Electrode Burr Inspection method:

1) Micro Scope 2) Lupe / Loupe 3) Visual inspection 4) Others - Mold Regrinding Time : ≤ 5 Time

- Cell Cleaning Function : Electrode cleaing from top to bottom separtely. (Ionizer + Turbo Brush & Dust Collector + Air Knife)

- Cell Vision Inspection : Dimension Check + Surface Inspection(Faulty Coating Inspection)

- Punching Counter : Pouching Times HMI Display(Manager Mode, Reset Function, Alarm Function)

Specification

* All specifications are custom designed according to customer's needs

| Items | Specification | Remark |

|---|---|---|

| Cell Size | T.B.D | T.B.D |

| Capacity (PPM) | T.B.D | T.B.D |

| Wrapping | Automatic | |

| Cutting, Taping | Automatic | |

| Stacking Precision | < 0.2mm | |

| Electrode Loading | Magazine(≥ 1,000 Sheets) | |

| Stack Height | T.B.D | T.B.D |

| Control | PLC, Touch Panel | |

| Dimension (WxLxH) | 1,550(W)*1,100(L)*2,000(H) | |

| Dimension (WxLxH) | 1550*1100*2000 |

Contact us

- Pouch Cell Ass'y