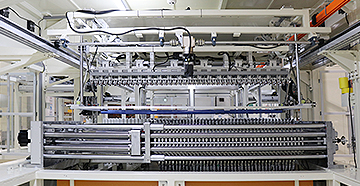

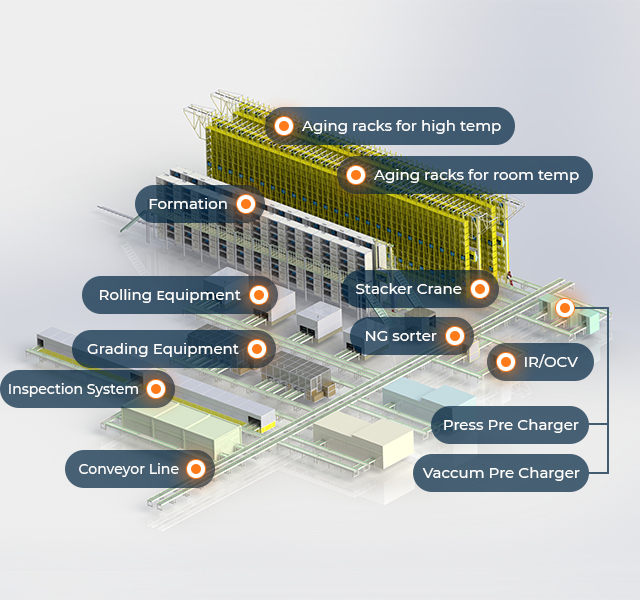

WONIK PNE Formation system is designed for formation process for lithium batteries and EDLC. We provide turn-key solution of formation from charge/discharge process to logistics system. It is suitable for any type of batteries such as cylindrical, prismatic, pouch and others. IT system enables remote control of each facility and assures data integrity. The system is protected by various safety functions and fire extinguishing system and customized and designed according to customer’s requirements. With know-how based on a great deal of experience, we provide highly reliable and secure system.

APPLICATIONS

-

Cylindrical Battery

-

Prismatic Battery

-

Polymer/Pouch Battery

-

EDLC

-

Etc

COMPONENTS

Formation

Press Pre Charger

Vacuum Pre Charger

Aging Rack

IR/OCV

NG sorter

Granding Equipment

Stacker Crane

Conveyor Line

Rolling Equipment

Inspection System

IT System

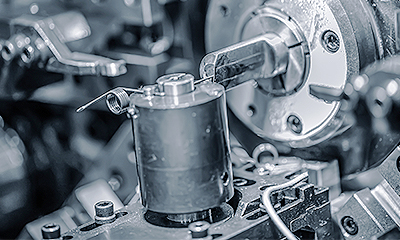

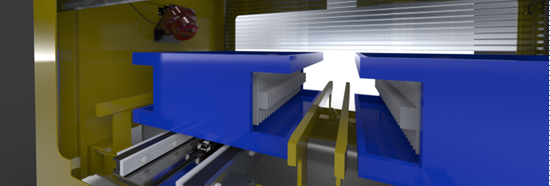

- Formation

- The Formation is charging/discharging equipment in battery production lines such as Li-Ion, Li-Polymer, Ni-MH and others.

Specification* All specifications are custom designed according to customer's needs

| TYPE | Linear or Regenerative |

|---|---|

| Voltage | 2.5 ~ 5V |

| Current | 0.6 ~ 200A |

| Volt. Accuracy | ±0.04% F.S |

| Volt. Resolution | ±0.04% F.S |

| Current Accuracy | ±0.05% + 0.05% rdg |

| Current Resolution | 16bit |

| Current range | Max. 3 Range |

| Control mode | CC, CV, CC/CV, OCV |

- Formation line(charger/discharger) for Li-ion cells or others

- Suitable for the mass production line

- Automatic production with IT system

- Interface between electrical part and automatic, semi-automatic or manual type of jig part

- Accurate and rapid control in real-time

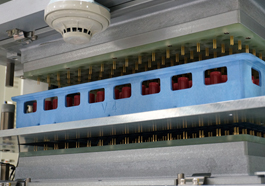

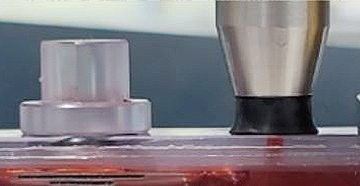

- Press Pre Charger

- The Press pre-charger is an initial charging device with heat pressure for a pouch battery to help forming SEI layer and improving battery erformance

- Uniform pressure press

- Uniform heating control

- High precision control

- Automatic Production with IT System

- Safety function: OTP, OPP, EMG Switch, Door Interlock, Smoke detection, Temperature detection etc.

Specification* All specifications are custom designed according to customer's needs

| Machine capacity | 0~N ppm | |

|---|---|---|

| Pressure | Control | Servo motor |

| Range | 200 ~ 10,000 kgf (Max 10 kgf/㎠) | |

| Resolution | ±20 kgf(@200 ~ 1,000 kgf) ±2 %(@1,001 ~ 10,000 kgf) |

|

| Stabilization Time | 60 s | |

| Heating Control | Method | Heating pad |

| Range | Room temp ~ 100 ℃ | |

| Temp Tolerance | ±2 ℃ | |

| Temp. Control | Able to temp control per each plate | |

| Temp. sensor Resolution | ±1 ℃ | |

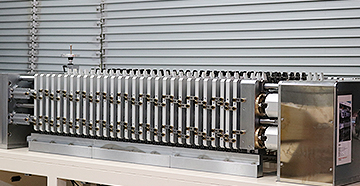

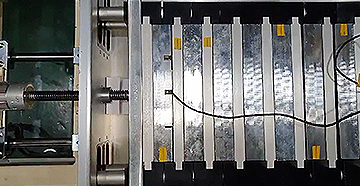

- Vacuum Pre Charger

- The Vacuum pre-charger is exclusively for prismatic/cylindrical batteries and is a facility that removes the gas generated in the batteries during pre-charing

- To help degassing with vacuum

- Individual vacuum control

- Able to operate under heavy load

- Automatic adjustment of cell fixture by motor

- Safety function: OPP, UPP, EMG Switch, smoke detection, temperature detection etc.

Specification* All specifications are custom designed according to customer's needs

| Method | Vacuum pump |

|---|---|

| Range | +10 kPa ~ -101 kPa |

| Meas. Resolution | 0.1 kPa |

| Setting Resolution | 1 kPa |

| Accuracy | ±3 kPa |

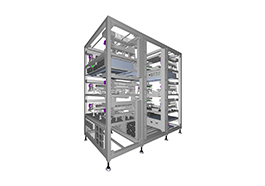

- Aging Rack

- The rack to store battery trays at high or room temp in a formation process

- Efficient design according to factory height

- Alarm & detection smoke and temperature by sensors

- Able to install firewalls (left/right/up/down)

- A separate room should be installed for high temp.

- High durability design with steel

- IR/OCV

- The IR/OCV is an instrument to measure OCV and internal resistance of cells and capacitors

- Analyzing the internal resistance of battery cell and capacitor

- Evaluating the quality of batteries with quick measurement for internal resistance spectrum

- Measuring OCV(Open circuit voltage)

- Able to fix Measurement frequency (1Khz) or make a selection (Option)

- Providing multiple contact points such as auto/semi- auto/manual type

- Measuring time : Within a few seconds at a single frequency (1KHz)

- Able to measure multiple battery cells by multi contact points at once

- Able to use R&D equipment through the frequency and current changing

- NG sorter

- The NG sorter is equipment to select faulty batteries based on the inspection data after charging/discharging or IR/OCV measuring process

- Improve safety in aging process by pre-grading

- Separately sort batteries required re-work

- Criteria for faulty batteries can be set by a user

- Manual type : Alarm when a tray for faulty batteries is full

- Automatic type : Trays are ejected automatically using conveyor system

- Safety function : Door interlock

- Granding Equipment

- A device that classifies batteries according to the grading criteria

- Accurate classification of batteries using robots

- Able to design the equipment fitted to rating Qty required

- Able to set operation rating ranges within designed grade ranges

- Continuous working function if the power is on within 30 min. after power failure

- Manual type : Alarm when a tray for faulty batteries is full

- Automatic type : Trays are ejected automatically using conveyor system

- Safety function : Door interlock

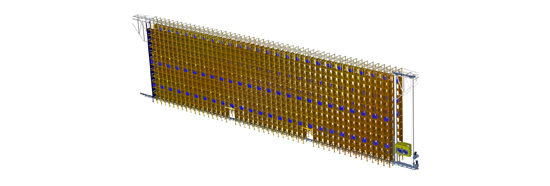

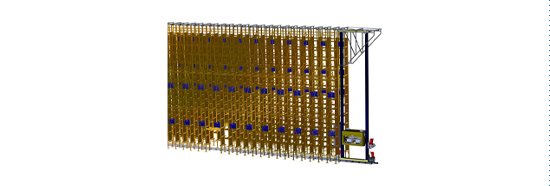

- Stacker Crane

- The Stacker Crane is logistic equipment to move trays with horizontal/vertical movement between aging racks and charging-discharging facilities

- Excellent for transporting trays to multi-layer shelves

- Manual or remote control

- Stacker cranes for high temp.

- Detecting trays position and preventing trays from out of the position

- Including a fire shutter and fire extinguishing system

- Monitoring status of trays or batteries in a carriage

- Congestion protecting function

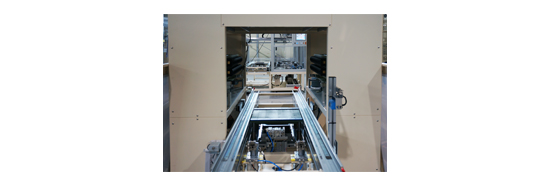

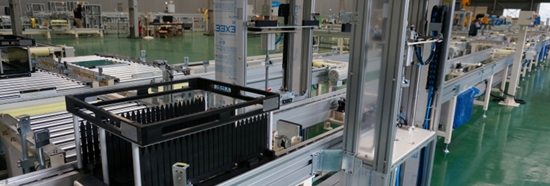

- Conveyor Line

- Conveyor system is logistic lines for transporting trays in formation system

- Designed conveyor system fitted to customer’s process

- Easy to modify it depending on the process

- Error prevention of entering trays by operators

- System design fitted to the trays weight

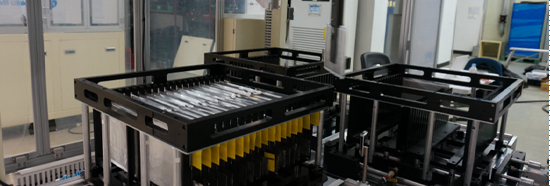

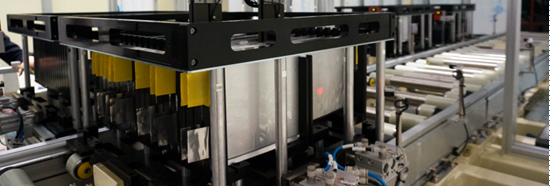

- Rolling Equipment

- A machine that improves performance by pressing cells through rollers and can help degas and electrolyte distribution

- To improve the solidity of the cells

- To help degas and electrolyte balance

- Enhance cells performance and life cycle

- Including roller cleaning function (Cleaning cycles can be set by users)

- Antistatic function

- Safety function : Door interlock

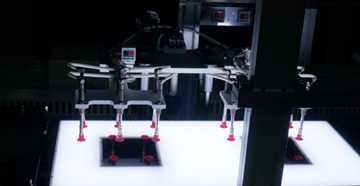

- Inspection System

- Inspection equipment which detects and scans ACIR/OCV, cell size, weight, surface and performs cell pressing.

- Automatic Inspection equipment at end of formation line

- Battery grading and faulty battery selecting based on the inspection data

- Able to add Inspection items depending on requirements

- Able to edit inspection preference and items by users

- Inspection items : ACIR/OCV, short, size, weight and surface of cells, position of barcode and cell pressing

- Safety function : Door interlock

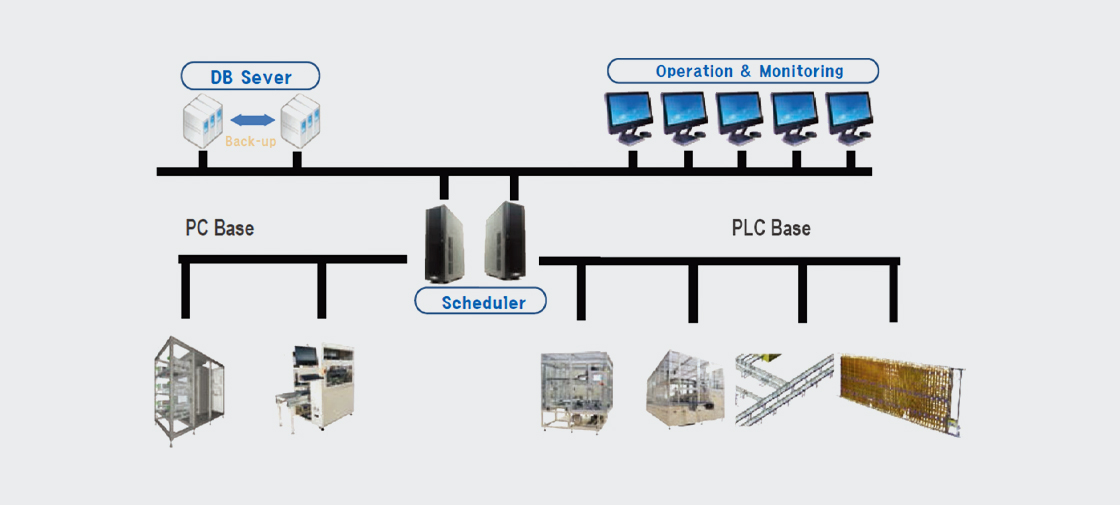

- IT System

- IT system which monitors and controls all facilities and working process

- Able to set administrators of each system Real time monitoring for status of each facility

- Easy to edit and manage process recipes

- Integrated monitoring system including process data and error histories

- Real time tracking for trays and status monitoring of logistics

- Immediately transporting operation commands [Stop, pause and etc.] to related facilities In case of an emergency

- Installed UPS in each facility in case of power failure

Contact us

- TURN-KEY FORMATION