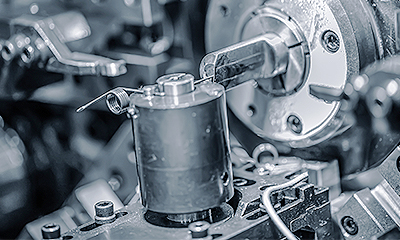

HIGH PRECISE &

WONIK PNE has been striving to develop battery test equipment more precise and accurate.

TURN-KEY

With reinforcing safety functions and advanced technology,

VIEW MORE

POWER & ENERGY

To further spread the green energy industry, WONIK PNE is making great effort

VIEW MORE

>Go to Contents

WONIK PNE News

Notice

2022.10.19

Wonik PNE-Sungeel Hi-Tech, Waste battery business MOU

Wonik PNE-Sungeel Hi-Tech, Waste battery business MOU Wonik PNE and Sungeel Hi-Tech will develop diagnostic evaluation equipment for waste batteries and next-generation high-speed dischargers.Wonik PNE and Sungeel Hi-Tech announced on the 17th that it has signed a memorandum of understanding (MOU) at its headquarters in Sungeel Hi-Tech, Gunsan, for "development of secondary battery characteristic diagnostic equipment and next-generation high-speed discharge."Accordingly, the two companies will cooperate in developing △ next-generation high-speed dischargers and providing equipment for evaluating residual value of waste batteries for recycling and reuse of batteries.The company said, "Through a mutual agreement, we will improve the waste battery diagnosis and discharger market by developing residual value evaluation equipment for reducing emission time, reducing pollutants, recycling batteries, and reusing waste batteries.""As the amount of waste batteries increased significantly due to the rapid growth of the electric vehicle market, major minerals were also extracted from waste batteries.The recycling (recycling) and reuse markets are also expected to grow significantly.According to SNE Research, the global electric vehicle waste battery market is expected to grow to 600 trillion won by 2050.It is also expected that demand for IRA (U.S. Inflation Reduction Act) will increase recently. As it is difficult for the U.S. to meet the domestic supply and demand of battery materials within a short period of time, the reuse of minerals through recycling waste batteries is drawing attention as an alternative to the supply and demand of materials.A company official said, "If minerals extracted from waste batteries are reprocessed in North America, they are recognized as batteries produced by the U.S., the U.S., and FTA signatories."Park Dong-chan, CEO of Wonik PNE, said, "We will provide a total solution to manage the life cycle of batteries that are rough in their entire lives, from battery manufacturing solutions to waste batteries.""We will proactively develop equipment that can increase process efficiency and strengthen our competitiveness in the waste battery market," he said.Founded in 2000, Sungeel Hi-Tech is a domestic waste battery recycling company. It is the only company in Korea that has a recycling batch process. The company operates recycling facilities in six countries, including Korea, Hungary, Malaysia, China and India. Recently, it established a waste battery recycling plant in Stephens County, Geor https://www.edaily.co.kr/news/read?newsId=02358326632493904&mediaCodeNo=257&OutLnkChk=Y

Notice

2022.10.18

WONIKPNE-PIE, A battery production facility smart factory business MOU

WONIKPNE-PIE, A battery production facility smart factory business MOU WONIK PNE and PIE(A smart factory software solution company) announced on the 12th that it has signed a memorandum of understanding (MOU) for technical cooperation.The business agreement ceremony held at Wonik PNE's office in Suwon, Gyeonggi-do on the 6th was held by PIE CEO and WONIKPNE CEO.It was held with major officials in attendance.With this agreement, Wonik PNE will lay the foundation for building a manufacturing intelligence factory by applying smart factory technology to the secondary battery mass-production processThe plan is to digitize the manufacturing process.PIE supports Wonik PNE's digital innovation strategy to be accelerated through its portfolio of industrial inspection equipment and knowledge sharing in the battery industry. It will also contribute to the development of the rapidly growing battery industry by solidifying its position as a technology partner to advance battery mass-production facility manufacturing technology and increase efficiency.Specifically, it will work on the smart factory business by developing and upgrading ▲ smart factory software solutions ▲ optimizing data-based facilities ▲ maximizing efficiency of mass-production equipment. Through this agreement, Wonik PNE plans to strengthen its professional manufacturing solution capabilities and optimize data-based facilities such as automation of manufacturing processes and implementation of artificial intelligence (AI).An official from Wonik PNE said, "It is essential to build a smart factory to improve battery quality competitiveness and maximize manufacturing supply chain efficiency."PIE is a company specializing in integrated inspection solutions that combine machine vision, non-destructive inspection technology and AI. It independently developed an industrial intelligence platform LISA (Look'In Smart With AI) by combining deep learning technology of its AI subsidiary "Aha Labs." In addition, the company's AI-based integrated smart factory solution "DataCamp" can collect, analyze, monitor, and predict data of manufacturing lines. It is growing rapidly by securing global companies such as major battery manufacturers and overseas automakers as customers through this solution. https://www.ddaily.co.kr/news/article/?no=248616

Notice

2022.10.17

WONIKPNE-MONA ELECTRIC, Expansion of secondary battery business MOU

WONIKPNE-MONA ELECTRIC, Expansion of secondary battery business MOU Wonikpne and Mona Electric announced on the 4th that they have signed a memorandum of understanding (MOU) to "expand secondary battery characteristics evaluation and diagnosis business."Through this mutual cooperation, the two companies will work to upgrade and intelligence secondary battery inspection and mass production equipment by developing ▲ battery quality inspection through development of ▲ battery characteristic diagnosis algorithm ▲ battery quality inspection through development of SOH (degraded state) rapid diagnosis.The solution is an artificial intelligence-based algorithm that can quickly infer the cause of battery quality and defect based on battery charging/discharging and impedance data. The two companies plan to apply the algorithm to equipment that controls the entire battery life cycle from battery production to recycling.First of all, the cell quality and performance are evaluated by applying it to facilities and inspection equipment for battery production and R&D. After that, it will be used for residual value analysis equipment for battery recycling and reuse to provide a service that encompasses battery life cycles.Mona Electric, a battery diagnosis company composed of domestic and foreign experts in electrochemical and big data analysis, develops a battery characteristic and quality analysis solution through battery impedance analysis and provides the solution to automobile OEMs.An official from WONIK PNE said, "Through this mutual cooperation, WONIK PNE will be reborn as a company that provides AI-based battery total solutions beyond equipment manufacturing," adding, "We will become a total solution company that contributes to fostering the battery and electric vehicle industries."

PNE SYSTEMS

A company making effort to keep the future

VIEW MORE